Plant And Equipment Of Colloidal Silica

Colloidal Silica, Colloidal Silica Manufacturer, Colloidal.. containing detailed information about Colloidal Silica fuel ethanol plant, equipment, sdi reduction and colloidal silica removal

WhatsApp)

WhatsApp)

Colloidal Silica, Colloidal Silica Manufacturer, Colloidal.. containing detailed information about Colloidal Silica fuel ethanol plant, equipment, sdi reduction and colloidal silica removal

Colloidal silica is nonionic, and is typically found in surface waters. It creates problems in water treatment because of its stability as an unionized compound, which makes it difficult to remove using ion exchange processes.

plant and equipment of colloidal silicaplant and equipment of colloidal silica Construction Waste Crusher Construction waste refers to the construction, constru

#0183;#32;A novel solid particle system with a nanomatrix structure and without surfactant for the oral delivery of insoluble drugs was prepared. This used a combination of pHsensitive polymethylacrylate and nanoporous silica, in order to improve the drug absorption using only pharmaceutical excipients and a relative simple process.

FMI Analyses the Impact of COVID19 and Updates Forecast of Colloidal Silica Market By Application Pulp amp; Paper, Metals amp; Metallurgy, Electronics amp; Semiconductors, Chemicals, Paints amp; Coatings, Building amp; Construction, Textiles amp; Fabrics; By Product Type Alkaline Colloidal Silica, Acidic Colloidal Silica, Modified Colloidal Silica, and Ordinary Colloidal Silica.

The Panel noted that among the types of SAS ( silica gel, precipitated silica, pyrogenic (fumed) silica and colloidal silica (silica sol)), colloidal silica is not authorised as a food additive (E 551). The food additive, silicon dioxide (E 551), is a material comprised of aggregated nanosized primary particles.

#0183;#32;Understanding Silicates and Colloidal Silica Densifier Technology Published on December 12, 2017 December 12, 2017 59 Likes 7 Comments

LUDOX #174; colloidal silica improves the performance of your products as inorganic binders, reinforcing and strengthening agents, refractory bonding agents and sur face modifiers. As a binder, it provides excellent strength and adhesion in catalyst washcoats and catalyst structures, precision investment casting molds, insulation boards and other refractory fiber based parts.

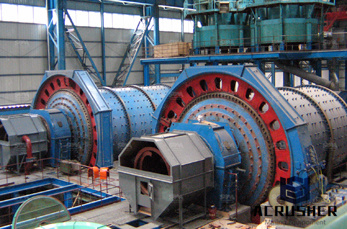

plant and equipment of colloidal silica,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plant

Colloidal silicas are most often prepared in a multistep process where an alkalisilicate solution is partially neutralized, leading to the formation of silica nuclei. The subunits of colloidal silica particles are typically in the range of 1 to 5 nm. Whether or not these subunits are joined together depends on the conditions of polymerization.

Colloidal Silica Problem Chemical plant design . nbsp 0183 32 No tests ever showed reactive silica in the demin water but colloidal silica does not show up on such tests Colloidal silica is notoriously difficult to detect in low ppb concentrations and only a few labs can provide analyses Even those lab results have poor resolution The cutoff for detectability at one lab was 100 ppb colloidal

Colloidal (solgel) silica particles typically have a spherical or oblong shape with a relatively uniform particle size distribution. CABOSIL TGC series of colloidal silica products are often used in electrophotography to enhance toner durability and improve print quality.

In a polymer resinbased matrix, the surface groups of silanemodified silica particles can react and crosslink with resin groups providing additional binding for the coating system. Antisoiling Silica particles in colloidal silica dispersions have many surface hydroxylsilanol groups, which are

Plant And Equipment Of Colloidal Silica. plant and equipment of colloidal silica Ludox colloidal silica is available in 220 lite gallon polyethylene nonreturnable drums and 1100 liter275 gallon bulk drums in north america it is also available in tank trucks ludox colloidal silica products are not considered hazardous by international transport regulations

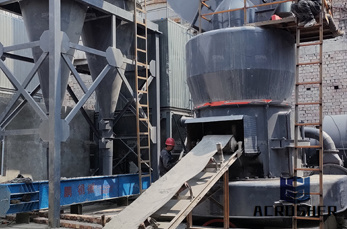

When installing tanks and equipment for colloidal silica, it is important to avoid trapping product in low points in pipes and tanks to reduce the risk of organic growth. If allowed to dry, colloidal silica can also form silica deposits that are very difficult to remove. Dried silica solids can result in

Fumed Silica also known as Colloidal Silica is a filler often used in epoxy. If you''ve ever though about building a boat or have actually built one using epoxy, you have most likely run across fumed silica, and wondered what it is and what it''s characteristics are.

The most common material for modifying the flow properties of a resin mix is colloidal silica. This is a very fine powder which is added in conjunction with other fillers to thicken mixes and reduce their flow on vertical surfaces (increase thixotropy).

WhatsApp)

WhatsApp)