Small production ball mill for ore grinding YouTube

#0183;#32;This is a new product we are developing. It is a 3''x6'' continuous ball mill for small scale production at about 1 tph. This video shows walks through some of...

WhatsApp)

WhatsApp)

#0183;#32;This is a new product we are developing. It is a 3''x6'' continuous ball mill for small scale production at about 1 tph. This video shows walks through some of...

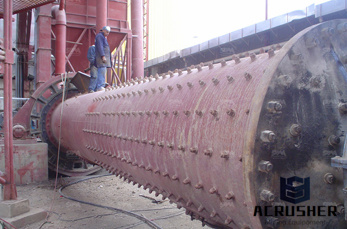

Ball mill has many types, such as, tube ball mill, cement ball mill, superfine ball mill and energysaving ball mill, overflow ball mill, chinaware ball mill and grid ball mill. Ball mill grinder or ball machine is mainly used to grind materials in mineral, cement, refractory, chemical and other industries, with dry

The ball mill machine runs smoothly and steadily with reliable performance. Features of ball mill machine: 1. The main shaft of the ball mill machine or small ball mill adopts the large diameter double center adjustable bars with little abrasion and low energy consumption, which makes the mill easy to

ore dressing disadvantages ball mills,Slide the saddle forward so that the ball screw is now sticking out the hole in the base far enough to slide the Yaxis motor mount onto the end of the ball Get Price ore dressing blake ball mill disadvantages

Ore Dressing Mineral Ball Mill. Grinding mills types working principle applicationsgrinding mills types working principle applicationsAug 17 2018 rod mills these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles rod mills can accept feed, ore dressing mineral ball mill

Ore Dressing Ore Components Of A Hydrocone Ball Mill . Tertiary Ball Mill Function Tertiary ball mill function functions of the dry ball mill ertiary ball mill function grinding mill equipmentertiary and regrinding duties in dry or wet processes and in either open the use of the default appearance function in the ball mill modelhas mixed the ore Read More Replacing Cs Cone Crusher.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

We sell Small Ball Mills from 2 to 6 (600 mm X 1800 mm) in diameter and as long as 10 (3000 mm) in length. This mill may be used for batch or intermittent grinding, or mixing of dry or wet materials in the ore dressing industry, metallurgical, chemical, ceramic, or paint industries.

China Ball Mill Equipment Manufacturer Rotary Dryer Sand . Ball Mill Equipment Rotary Dryer Sand Making Machine manufacturer supplier in China offering Wet and Dry Silica Quartz Stone Power Ball Mill Good Quality Ball Mill Stone Mills for Grinding Worldwide Hot Selling Welding Jaw Stone Crusher for Sale and so on mineral ore dressing equipment Powder Grind Ball Mill in Mining Industry FOB.

Ball mill plays an essential role in the mineral processing some small and old mines are still using the oldfashioned is not perfect, such as lower tank ledge, internal overflow groove, overlapping scraper, etc. Latest News Xinhai CuPbZn Ore Dressing Process. It is reported that more than 90% of nonferrous metal ores

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products amp; service from China.

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant.

The ball load should be 4058% of the total internal mill volume, and the material to be ground should fill only the voids between the balls (a maximum of twice the ball space) Viscosity, the order of filler addition, and the quantity of material should be chosen so as not to cause a viscosity increase above the specified range, since the milling efficiency drastically decreases at that point

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Mineral Ore Processing Ball Mill Crusherball Mill. Crusher ball mill cast iron ball for mineral processing crusher ball mill cast iron ball for mineral processing separating the ball mill is one of three mills in the mineral processing plant and is the heart of the concentrate recovery operation capable of grinding up to 45 million tonnes of ore per annum to a fraction size of about 125

Technology of Ore dressing ball mill Ore dressing ball mill requires ore no more than 20mm particles. When the ball and ore enter the grinding bin of the ball mill from the grinding tail hopper, the ball and ore are driven upward by the ball mill rotating at a uniform force and kinetic energy cause the ball and ore to be extruded and ground, and then rise to a certain height.

WhatsApp)

WhatsApp)