Used Ballmills For Sale King

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

WhatsApp)

WhatsApp)

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

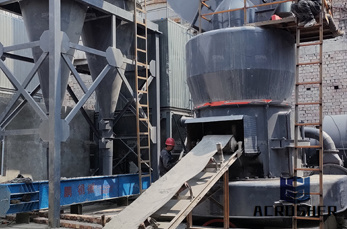

Gold Mining Ore / Mineral Processing Plant Wet Ball Mill Working Principle The transmission device drives cylinder to rotate. Materials and water are fed from the feeding end of cylinder and materials are grinded by impact and grinding of steel balls and ores into fine particles.

This ball mill is used in mining industries.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

China Ball Mill manufacturers Select 2020 high quality Ball Mill products in best price from certified Chinese Plastic Machinery manufacturers, Milling Machine suppliers, wholesalers and

large ore wet ball mill machineoldstationhotel. Ball Mill machine Ball mills,Grinding mills,Ball . Introduction Ball mill machine is the key equipment for recrushing the materials after they are primarily crushed. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate. Get

offers 1,111 wet ball mill products. About 70% of these are Mine Mill, 17% are Grinding Equipment. A wide variety of wet ball mill options are available to you, such as condition, local service location, and applicable industries.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

Grinding Machine, Grinding Equipment, Milling Machine manufacturer / supplier in China, offering High Quality Mining Ore Wet Stone Grinding Ball Mill for Sale, Hot Sale Mining Equipment Vacuum Rotary Drum Filter with Low Price, High Quality separation High Single Spiral Classifier for Sale and so on.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mills of greater length are termed tube mills, and when hard pebbles rather than steel balls are used for the grinding media, the mills are known as pebble mills. In general, ball mills can be operated either wet or dry and are capable of producing products on the order of 100 um.

China Wet Process Ore Minerals Grinding Ball Mill, Find details about China Ball Mill Price, Grinding Machine from Wet Process Ore Minerals Grinding Ball Mill Yantai Fulin Mining Machinery Co., Ltd.

Wet Grid Ball Mill . Capacity: Feed Size: 25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

#0183;#32;The wet pan mill is named by the diameter of roller. 1300, 1350, 1400, 1500, 1600 is suitable for selection of iron ore, molybdenum ore,lead ore,zinc

Application of ball mill machine: Ball mill is used for grinding of various ores and rocks, widely used in nonmetal mines, ferrous and nonferrous metal mines, construction material, hydraulic engineering etc. 1. Iron ore beneficiation line 2. Copper ore beneficiation line 3. Gold ore beneficiation line 4. LeadZinc ore beneficiation line 5.

WhatsApp)

WhatsApp)