Direct Rope Haulage system definition, Diagram, Safety

Direct rope haulage, underground mines transport system haulage system surface install rope haulage tubs

WhatsApp)

WhatsApp)

Direct rope haulage, underground mines transport system haulage system surface install rope haulage tubs

As haulage powers increased to match the higher production requirements, the haulage drive was moved onboard the shearer and the rope replaced with a chain. With further increases in haulage power the chain size grew to 22mm, however, the presence of a highly tensioned chain along the length of the face created a serious safety issue.

Rope Haulage System Mining Wikipedia Crusher USA. About rope haulage system mining wikipediarelated information:by the later middle ages the crown also regulated mining in dean through the office of gaveller or

Mining Industry demands the best in class wire rope, which can perform under one of the most adverse working conditions in the world. Usha Martin, an Industry leader in mining rope segment, provides ropes with excellent breaking load capacity and higher resistance to fatigue, wear, and abrasion helping users to achieve reduced downtime, longer life, and low maintenance cost.

#0183;#32;Belt conveyor and Haulage system in the mine 1. DISTINGUISH THE MINE PERFORMANCE BY CONVEYOR BELT AND HAULAGE SYSTEM OF TRANSPORTATION A mini project Submitted in partial fulfilment of requirements for award of Bachelor of Technology and in Mining Engineering By Anurag Kumar Jha Exam Roll no. SESSION DEPARTMENT OF MINING

Introduction to Rope Haulage Road Signalling: The principal requirements for a rope haulage signalling system are that it must be possible to ring signals from any point along the haulage road, and that any signal which is rung can be heard at all the main stations.

Mining Rope Haulage System Rope haulage system mining wiki attachment mine railway wikipedian the 19th century after the mid1840s, when the german invention of wire rope became available from manufacturies in both europe and north america, large stationary steam engines on the surface with cables reaching underground were commonly used for mine haulage.

mining rope haulage system The mine wire rope haulage system transports men and materials in and out of the mine. The haulage rope broke when the load was in the lower part of the drift. Three of the four men in the dolly car managed to scramble out, but a fourth remained inside until the vehicle came to a stop. Hot.

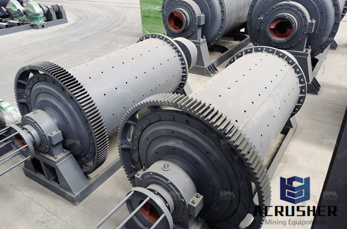

Mining Rope Haulage System rope haulage system mining. rope haulage system mining, From large primary jaws and gyratories to cones

#0183;#32;End less rope haulages In this system there are two parallel tracks side by side. One for loaded tubs and another for empty tubs and the endless rope passing from the driving drum located at out bye end of the haulage road to the in bye end and back again via a tension bogey. The tubs loaded as well as empties are attached to the rope with regular interval with the help of clips so that the

Table of ContentsTransportation of Ore and WasteTramming and HaulingHand TrammingAnimal HaulageTonMiles Obtained Under Varying ConditionsMechanical HaulageLocomotive HaulageTramming and Haulage CostsScrapingConveyor Systems Transportation of Ore and Waste For the purpose of this discussion, transportation signifies the operations involved in transporting ore and

The mine wire rope haulage system transports men and materials in and out of the mine. The haulage rope broke when the load was in the lower part of the drift. Three of the four men in the dolly car managed to scramble out, but a fourth remained inside until the vehicle came to a stop. Hot.

The haulage system was a bidirectional endless rope haulage driven by a two an average of one foot in every eight and it served every district 5Teversal, One of Becker Mining System''''s most popular products is a floormounted ropedriven trap rail haulage system, A mining company in India intends to produce calcium carbonate site stone to

b)Over Rope Endless Rope Haulage: If the rope passes over the tubs, it is known as over rope endless rope haulage. In this system rope is unaffected by wet floor amp; liable to wear amp; tear. The rope is at better working height amp; a system is generally used for undulating roadways. get price

#0183;#32;This is my Rope railway, it uses my homemade boiler, and a marklin 4097 engine unit. it will have track and wagons to pull when completed. the traction engine was used as a test load.

system are the ore/coal haulage and personnel transport systems, since the decisions are very difficult and not always possible in isolation from the other two. Important factors that affect the selection of the materials and equipment transport system are as follows: 1. Quantity (volume and weight) and size of materials and equipment. 2.

1)Direct Rope Haulage. a)Single Drums Direct Rope Haulage: This is simplest system of rope haulage. It consists of one track, one rope amp; one drum which are connected to a motor through gears. One end of the rope is connected with the train of tubs on the track amp;

WhatsApp)

WhatsApp)