3D Animation Demo amp; working site of Ball Mill YouTube

Offical website: Alibaba website: Product webpage:

WhatsApp)

WhatsApp)

Offical website: Alibaba website: Product webpage:

The IsaMill is an energyefficient mineral industry grinding mill that was jointly developed in the 1990s by Mount Isa Mines Limited (quot;MIMquot;, a subsidiary of MIM Holdings Limited and now part of the Glencore Xstrata group of companies) and Netzsch Feinmltechnik (quot;Netzschquot;), a German manufacturer of bead mills. The IsaMill is primarily known for its ultrafine grinding applications in the

An electric screwdriver (these are fairly cheap, I got mine for 10) 3. A bolt, a nut and maybe a washer. 4. Epoxy putty. 5. Steel or lead balls which in my case I substituted with screwdriver bits that I got for 3. 6. A vise clamp to hold down your ball mill.

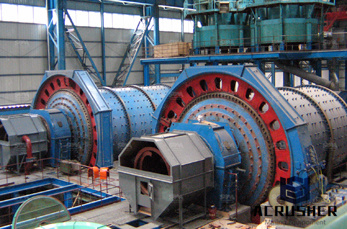

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

Our mills run the ore through ball and rod mills to reduce it to the proper size for our flotation process. Flotation separates the copper, zinc and lead. After separation, the various concentrates are dried to the consistency of a damp powder before being stored in our enclosed storage and shipping facility.

Factory Price Gold Ore / Copper Mine,Lead Zinc Grinding Wet Ball Mill Supplier, Find Complete Details about Factory Price Gold Ore / Copper Mine,Lead Zinc Grinding Wet Ball Mill Supplier,Ore Ball Mill,Gold Ore Grinding Wet Ball Mill,Wet Ball Mill Supplier from Mine Mill Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Lead Mine Conservation Area is in northeastern Dallas County, 40 miles south of Lake of the Ozarks, 12 miles north of Bennett Springs, five miles east of Tunas, and 21 miles northeast of Buffalo. The area provides about two miles of Niangua River frontage and has

Factory Price Air Swept Steel Mill Machine Stone Coal Grinding Airswept Ball Mill Equipment, Find Complete Details about Factory Price Air Swept Steel Mill Machine Stone Coal Grinding Airswept Ball Mill Equipment,Grinding Ball Mill,Cement Making Ball Mill,Grinding Machine Mill from Supplier or ManufacturerHenan Hongji Mine Machinery Co., Ltd.

lead mine swept ball mill systems. Ball Mills Know More. 23 Dec 2017 Load Capacity of Trunnion Bearings; Ball Mill amp; Rod Mill Liners gears are made of high grade cast iron with cast teeth which are made from a full pattern and not a sweep pattern. This applies particularly to gold and lead ores.

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

In the ball mill, Lead is converted to Lead Oxide, by grinding and oxidation process, which is an exothermic process. In this process, heat is generated and temperature of oxide is increased, to control the temperature with in the operating range of 115 to 135C, the ball mill temperature is controlled with constant flow of air and with the water spraying system controlled through solenoid valve.

#0183;#32;Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill.

Union Process is the source for the most uptodate information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

lead mine swept ball mill systems. Wind Swept Coal Mill coal Powder Making Machine Buy Coal . MG type wind swept steel ball coal mill is one of four auxiliary machines in heat power it s the main equipment in coal powder preparation and it s mainly used for powder milling various hardness coals It s also suitable for coal and ore milling system

offers 2,176 ball mill for lead mine products. About 42% of these are mine mill, 1% are other fabrication services, and 1% are grinding equipment. A wide variety of ball mill for lead mine options are available to you, such as ac motor, dc motor, and stepper motor.

Part of the problem appears to have been inefficiency in smelting the ore, much ore thus being wasted. This indicates that the furnaces may not have been enclosed designs such as were used at Wanlockhead lead mine. Papers on the mine include a 1792 design for a Smelting Mill

WhatsApp)

WhatsApp)