Modeling of Operating Parameters for Wet Ball Mill by

Experimental results show that proposed method has higher accuracy and better predictive performance than the other approaches. I. INTRODUCTION lthough wet ball mills have been used widely in the

WhatsApp)

WhatsApp)

Experimental results show that proposed method has higher accuracy and better predictive performance than the other approaches. I. INTRODUCTION lthough wet ball mills have been used widely in the

Effect of ball size and powder loading on the milling efciency of a laboratoryscale wet ball mill Hyunho Shin a, Sangwook Lee b, Hyun Suk Jung c, JongBong Kim d, n

Wet milling is mainly applied to isolate starch, but other coproducts that are interesting for food applications are the proteinrich and fiberrich fractions. Typical wet milling includes the following steps: 1. Cleaning of the grain; 2. Soaking in an aqueous solution (often including alkali); 3.

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

Grate discharge Wet Overflow discharge Wet Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure

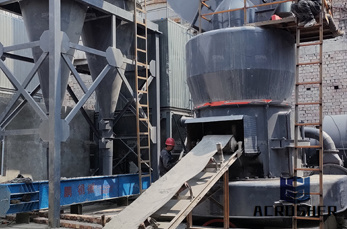

process description of profile wet ball mill. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent.

profile wet ball mill machine manufacturers. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent.

The result of this test is known as the Wet Ball Mill (WBM) value. Apparatus The following apparatus is required: wet ball mill machine, consisting of a watertight steel cylinder, closed at one end, with inside dimensions of #177; 3 mm ( #177; 1/8 in.) in diameter and #177; 3 mm ( #177; 1/8 in.) in length.

profile wet ball mill y; profile wet ball mill y. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent.

Wetbulb calculator applications. The wetbulb temperature might not be a widely known measure, but it has some valuable functions: Construction different materials react differently to different humidities, so this temperature is needed when designing a building in different climates.. Snowmaking snow production needs low temperatures and when the humidity decreases the temperature rises.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

1/6/2014#0183;#32;The discussions in Section 2 for dry mills can also be applied to the wet mills up to the point just before the balls reach the pulp surface at point (x 1, y 1). See Fig. 3 for the ball movement curve in the pulp of a wet mill. Download : Download fullsize image; Fig. 3. The ball movement in the pulp in a wet mill.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

15/6/2012#0183;#32;Steps in ball milling method; 1. As the name suggests, the ball milling method consists of balls and a mill chamber. Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill

Results and discussion 65 Ball size distribution effect 65 Breakage mechanisms in a ball mill 22 Breakage zones identified in a ball load profile 33 Breakage function of a 850#215;650 microns normalizable quartz under various mill load conditions (D=195 mm, d= mm,

With more than 100 years of experience in ball mill technology, Metsos ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

#0183;#32;Wet Ball Value or Abrasion Testing Alternatives SETlabguy (Geotechnical) (OP) 7 Mar 06 18:00. We have a client requesting a wet ball value (TXDOT TEST METHODS 116E) or, as an alternative, an LA Abrasion Test. The problem is they don''t have enough material to run either test.

WhatsApp)

WhatsApp)