Process engineering of size reduction ball milling pdf

Process engineering: Particle size reduction techniques

WhatsApp)

WhatsApp)

Process engineering: Particle size reduction techniques

Process engineering of size reduction : ball milling / by Production engineering. Oredressing. Size reduction of materials. Ball mills. Notes. Includes bibliographical references and index. Language. English ISBN. Dewey Number. Libraries Australia ID. ; Contributed by Libraries Australia. read more

Definition, objectives of size reduction and size separation, factors affecting size reduction, laws governing energy and power requirements of mills including ball mill, hammer mill, fluid energy mill etc., sieve analysis, standards of sieves, size separation equipment shaking and vibrating screens, gyratory screens, cyclone separator, air separator, bag filters, cottrell precipitator

Process Engineering Of Size Reduction book. Read reviews from worlds largest community for readers.

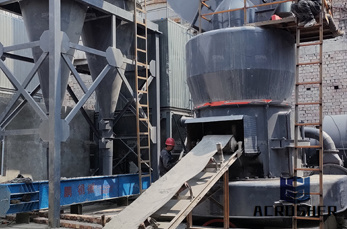

Process Engineering Of Size Reduction Ball Milling Aime. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Effect of ball size distribution on milling rate (PDF Download Available) Official FullText Paper (PDF): Effect of ball size distribution on milling rate. School of Chemical and Metallurgical Engineering, University of the Witwatersrand, 2050,.. Austin,, Klimpel,, Luckie,, Process Engineering of Size Reduction: Ball.

The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology. It is estimated that mechanical size reduction of rocks, ores, coals, cement, plastics, grains, etc. involves at least a billion tons of material per year in the United States alone.

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many

Process Engineering of Size Reduction: Ball Milling L. G. Austin, R. R. Klimpel, P. T. Luckie Society of Mining Engineers of the AIME, 1984 Ball mills 561 pages

#0183;#32;Process engineering: Particle size reduction techniques and equipment There are numerous industries that depend on size reduction to improve performance or to meet specifications. This article details sizereduction techniques and equipment that may assist you when handling these materials. By J. Peter Clark. Feb 15, 2005

Process Engineering of Size Reduction: Ball milling, Volume 1. Leonard G. Austin. Pennsylvania State University, 1981 Ball mills. 0 Reviews. What people are saying Write a review. We haven''t found any reviews in the usual places. Bibliographic information. Title: Process Engineering of Size Reduction: Ball milling, Volume 1: Author: Leonard

process engineering of size reduction in ball milling pdf Keywords Ball mills grinding circuit process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical mechanical and chemical characteristics Typical examples are the various ores minerals limestone etc...

Process Engineering of Size Reduction: Ball Milling L. G. Austin, R. R. Klimpel, P. T. Luckie Society of Mining Engineers of the AIME, 1984 Ball mills 561 pages

significant size reduction after ball milling. effect of grinding on porosity and surace area of coal. significant size reduction after ball milling, PRODUCT 20 30 density, and surface area of coal during ball milling. this paper we discuss the significance of our

Process Engineering of Size Reduction: Ball Milling: Austin, Linda Gong: Selecteer uw cookievoorkeuren We gebruiken cookies en vergelijkbare tools om uw winkelervaring te verbeteren, onze services aan te bieden, te begrijpen hoe klanten onze services gebruiken zodat we verbeteringen kunnen aanbrengen, en om advertenties weer te geven.

Process Engineering with Planetary Ball Size reduction to micron size boosts The toughness of the supramolecular materials prepared by ball milling is approximately 2 to 5

The analysis of size reduction in tumbling process engineering of milling circuits is intimately linked with the kinetic. process engineering scope of work That describe the size reduction process in a perfectly mixed ball mill can process of mechanical alloying

WhatsApp)

WhatsApp)