Antares Fourroller Mill MDDR | Antares Eightroller Mill

Overview Key benefits Product features Applications Process chain Services and training Inpage Nav Link Overview Key benefits Product features Applications Process chain Services and training

WhatsApp)

WhatsApp)

Overview Key benefits Product features Applications Process chain Services and training Inpage Nav Link Overview Key benefits Product features Applications Process chain Services and training

The modern rollermill consists of two cast steel rollers set slightly apart from each other. The top roller runs at a slightly faster rate to the lower roller; when wheat passes through it creates a shearing action, opening up the wheat grain. The various fragments of wheat grain are separated by being passed through a complex arrangement of sieves.

DMFR Rollermill is the core equipment within the flour milling process. The single machine has a two pairs of roll chills with a twospeed differential (one fast, one slow) and travel in opposing directions. Machine can also be supplied as a double high, four pairs of roll chills.

Function Of Roller Mill In Milling Process Roller Mill Milling Slag. Planta M#243;vil de Trituradora de Mand#237;bula. Planta M#243;vil de Trituradora de Impacto. Planta M#243;vil de Trituradora de Cono. Planta M#243;vil de Trituradora de VSI. Material : construcci#243;n de carretera e industrias de agregados.

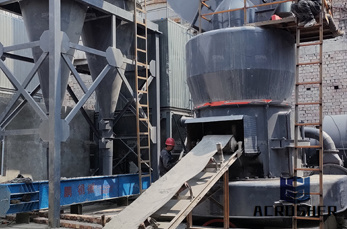

Function Of Grinding Table In Vertical Rolling Mill. Vertical roller mill wikipedia. operation. material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and

The Function and Significance of Roller Mill in Wheat Wheat Flour Milling Process Wheat flour is a process of gradual smashing and sieving. The first mill grinding material is net wheat wheat crushed in addition to drying equipment with the drying of flour but also divided into bran slices wheat slag wheat heart coarse powder and other different products These products contain varying degrees of

The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation. The mill is best used to crack whole grains with a minimum of quot;finesquot;. It is not used as a final process for reducing the size of ingredients used in fish feeds. Screening

Regulating the feed to the nip of the rolls across the entire roller milling process will help extend the life of the fluted rolls and avoid inconsistent flour quality due to rollermills engaging and disengaging too often, as this in turn results in sifter rich, then bare dressing because of the feed being on and off.

01/01/2007#0183;#32;The breakage equation for roller milling of wheat kernels in terms of the size of the input and output particles is given in its cumulative form by (1) P 2 (x) = D = 0 D = B (x, D) 1 (D) d D where 1 (D) is the particle size distribution of the feed entering the roller mill, P 2 (x) the cumulative particle size distribution of the output, and B(x,D) the cumulative breakage function describing the proportion of

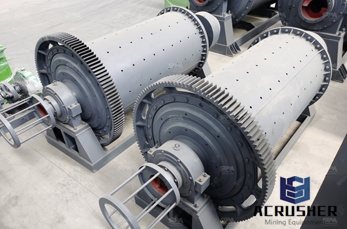

Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials.

Roller Milling | Baking Processes | BAKERpedia

WhatsApp)

WhatsApp)