THE MAKING(English Version) (314)The Making of Steel Balls

This edition of the series of programs explaining the technology used to produce items that are familiar in our daily life features Steel Balls. A bicycle

WhatsApp)

WhatsApp)

This edition of the series of programs explaining the technology used to produce items that are familiar in our daily life features Steel Balls. A bicycle

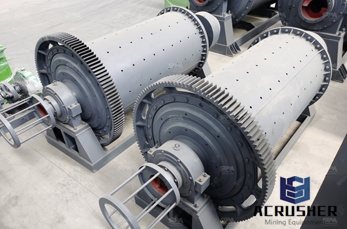

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium smaller grades are occasionally cylindrical (quot;pebs

#0183;#32;The ball mill produced by Fote Machinery shows good casting process performance, high mechanical properties and good heat treatment performance to minimize the wear during materials impacting. The grinding balls are mainly made of high manganese steel: it makes ball mill balls good toughness, good

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ball milling of graphite with appropriate stabilizers is another mode of exfoliation in liquid phase. 21 Graphite is ground under high sheer rates with millimetersized metal balls causing exfoliation to graphene (Fig. ), under wet or dry instance, this method can be employed to produce nearly 50 g of graphene in the absence of any oxidant. 22 Graphite (50 g) was ground in

Ball Mills Steel Ball Mills amp; Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Nov 12, 2020#0183;#32;Grinding Ball, Grinding Rod, Steel Cylpebs, Forged Steel Ball, Casting Ball, Forged Steel Ball Production Line, Hot Rolling Steel Ball Company Introduction Huafu Group is located in Zhangqiu City, Shandong Province, 45 Kilometers to the Jinan downtown, next to the 309 National Highway, enjoying firsthand Information and convenient traffic.

Ball Mill Machine. Grab Those Balls! Scroll down to content. Posts. Posted on February 21, 2019 February 22, 2019. Steel toecapped boots Not only do potholes jeopardize the safety and performance of pavement,

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation.

Grinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals. AISI steel grinding balls for ball mill applications typically have a tolerance of #177;/#177; and a density of to Exceptions . Get Price gt;

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it

Ball milling is one of the few unit operations that actual improve in performance and efficiency with increasing size. The ABBE Slice Mill is the same as the product mill and can replicate all mill operating parameters but with very little product. Materials: Abrasion Resistant Steel, Stainless Steel, Polyurethane or Rubber Lined.

#0183;#32;How to make qualified casting steel balls? This production line can meet your requirements to produce dia30mm to dia150mm. No air holes, no dis

Ball Mill an overview ScienceDirect Topics. Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

WhatsApp)

WhatsApp)