Home | Cement Australia

NEW: CemTrack vehicle tracking for bulk deliveries. Find a Stockist. Safety amp; Sustainability

WhatsApp)

WhatsApp)

NEW: CemTrack vehicle tracking for bulk deliveries. Find a Stockist. Safety amp; Sustainability

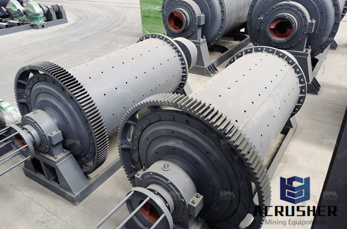

Vertical roller mill (VRM) Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Infrastructure: Steel Cement is building a UBE Vertical Roller Mill, Raw Material Storage and Handling Facility and a Finished Product Storage Silo to increase its ability to meet current and future purpose of this plant is to receive slag (which is a byproduct from hot rolling steel) via bulk cargo ships and process it into a valuable element that can be used in general blend

Cement Vertical Mill Structure: The vertical mill consists of a separator rotation system, a separator part, and an upper casing part upper casing with an inspection door and a feed port, a roller device, a transmission device, a tie rod portion, a disc seal, an upper and lower side, a side friction ring, and an unloading material ring, grinding disc adjusting device, air ring adjusting device

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGamp;GRIND modular and portable grinding stations. 25 a#241;os en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y clinker, silos

China leading provider of Vertical Cement Mill and Cement Ball Mill, Anyang Best Complete Machinery Engineering Co., Ltd is Cement Ball Mill factory. +. English English French German Italian Russian Spanish Portuguese Dutch Greek Japanese Korean

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills.

CEMENT ADDITIVES FOR VERTICAL MILLS 04 2. VERTICAL MILLS INTRODUCTION Thanks to the necessity to improve grinding efficiency and reduce operation costs, vertical mills have made their way into the cement industry. At first these new systems were employed for the grinding of solid combustibles and kilnfeeding raw meal. In the past decade,

Pfeiffer SE will supply Australias largest vertical roller mill for cement grinding to Australias leading cement cement mill for sale australia pakistan crusher,stone Gulin provide the cement mill for sale australia solution case for you. vertical mill of cement plant procedure for crushing cement

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

The OK Mill was originally designed for cement grinding. In 2017 we released the OK vertical roller mill for raw materials grinding. The OK Mills modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement Mill In Australia. Cement Plant Location Information for Australia Cement plant locations and information on Australia can be found below For full access to the database purchase The Global Cement Report 13th Edition. Send Email: [email protected] Send Inquiry Inquiry Online.

Vertical Mills. A significant portion of the cost to produce a ton of cement resides in the grinding costs. The industry standard for decades has been horizontal ball mills which rely upon heavy balls cascading inside a fast turning mill to crush the clinker into the fine cement powder.

#0183;#32;In view of the above constraints, Cement Australia made the decision to opt for a Pfeiffer vertical roller mill of the type MVR 6000 C6 coupled with a MultiDrive #174; system (Fig.), which will come equipped with 3 drive modules with a total installed power of 5520 kW.

WhatsApp)

WhatsApp)