What is the cleaning process for balls in Ball mill process?

For cleaning the balls in ball mill During milling of powder in planetary ball mill (WCvial with WC grinding Southeastern France to produce 40,000 tonnes/yr IPA that could start up in the

WhatsApp)

WhatsApp)

For cleaning the balls in ball mill During milling of powder in planetary ball mill (WCvial with WC grinding Southeastern France to produce 40,000 tonnes/yr IPA that could start up in the

Ball Size Distribution. As the mill starts, grinding action and throughput increases. However, after reaching a critical speed, the mill charge clings to the inside perimeter of the mill. Under this conditions, the grinding rate is significant reduced or stopped. All mills must operate less than Critical Speed

grinding ball mill do not starts Grinding Media Selection Grinding Mills CB Mills. CB Mills Inc is a manufacturing leader of superior products such as Grinding Mills, The media tends not to collide in the high energy areas of the mill, just in the, will be insufficient to start the media bed in motion and fluidize it completely.

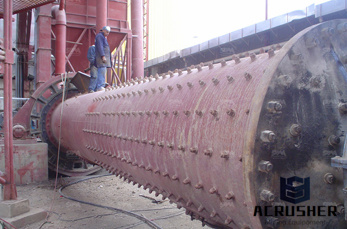

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding

Ball milling replaces potentially unsafe hand grinding of chemicals and compositions. a rock, or a big tree. If you can''t do that, barricading the ball mill with sandbags, stacks of firewood, 5 gallon buckets of water or dirt, or something similar is a Start of mill run, cabinet temperature: 30 degrees F 10 minutes into run, mill

#0183;#32;Ball mills are a special instrument used to break up hard solids into a fine powder. Do not use steel balls or other grinding media when milling flammable materials. Thanks! To make a ball mill, start by building a wooden platform and attaching a motor underneath it.

To participate in the 911Metallurgist Forums, be sure to JOIN amp; LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone elses

Planetary ball mills are perhaps the most commonly used ball mills in laboratories for the sample preparation of soft to hard, brittle and fibrous materials. The name of this mill type derives from its unique kinematics: the grinding bowls, which are mounted on the rotating sun disk, rotate in the opposite direction around the centre of this disk.

To help the grinding process, water and steel balls are added to the process which then form the charge in the mill. Ball mill charge contains a significant amount of steel balls and can become extremely heavy. For example, a large 24 foot ( m) diameter ball mill charge typically weighs around 2

Grinding balls making machine is widely used for grinding balls producing in foundries, including balls making machine: automatic casting grinding media molding line and manual metal mold; heat treatment furnace for grinding balls, contents quenching plant and tempering machine; the balls separator for separating the grinding balls with risers, runners and pouring gates; and then the lab

Ball Mill leaking. Sag Mill Bolt Testing. Sag Mill Leaking. Cracked Bolts. Worn out bolt Holes the structural bolts on mills are exposed to extreme loads during operation and after a period of time they start to relax and loosen off further, In many grinding plants mills which have metallic or rubber liners suffer from bolt breakage.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

Director, Global Engineering, Grinding Products. Dropped charge, also known as frozen or locked charge, occurs when solidified material inside a horizontal grinding mill does not cascade when the mill starts rotating at start up. Instead, it is lifted and then free falls onto the mill shell. Dropped charges experienced in large ball mills can be

#0183;#32;Ball mill is used to grinding ores or other materials after crusher, it is the mechanical equipment for getting finer particle products.

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a

grinding ball mill do not starts [ 5966 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

Note: Sometimes the mill will not start turning the jar when the switch it turned on, and the jar is sitting on the mill. The motor is not a capacitorstart motor, so it can have a challenge starting from a dead stop with a load on it. If this happens, simply lift the jar and allow

#0183;#32;Anyway, SAG mills can be calculated as inefficient, except they do not require a large grinding load like ball and rod mills. Capital and operating costs have to be compared, system vs. system in order to assist with the selection. The feed suitability visavis the grind method is critical.

WhatsApp)

WhatsApp)