manufacturing process of granite | Mining amp; Quarry Plant

manufacturing process of granite Iron beneficiation and About Us. SHANGHAI SHIBANG MACHINERY CO., LTD is one hightech enterprise, which involves Ramp;D, production, sales and

WhatsApp)

WhatsApp)

manufacturing process of granite Iron beneficiation and About Us. SHANGHAI SHIBANG MACHINERY CO., LTD is one hightech enterprise, which involves Ramp;D, production, sales and

The Countertop Fabrication Process Great Lakes Granite

A. Manufacturing Process During the processing of marble and granite, that takes place in Shaq AlThu`ban cluster, the raw stone block is cut as demanded either into tiles or slabs of various thicknesses (usually 2 or 4cm), using diamond blades.

Manufacturing Process McCannon Granite Company. Granite is cut from the quot;bedquot; of the quarry with a jet piercing machine that produces a flame burning at approximately 3,000 degrees Frenheit. This highvelocity flame, created by burning oxygen and fuel oil, is directed at the granite to be removed, causing a continuous flaking action.

Manufacturing Process McCannon Granite Company. Manufacturing Process ; Contact Us Granite is taken from quarry using a variety of tools and personnel. Often these blocks are

Granite (/ r #230; n t /) is a coarsegrained igneous rock composed mostly of quartz, alkali feldspar, and forms from magma with a high content of silica and alkali metal oxides that slowly solidifies is common in the Earth''s continental crust, where it is found in various kinds of igneous range in size from dikes only a few inches across to

Process of Granite Manufacturing. Granite, these days, is manufactured in stateoftheart facilities in India. The whole process of granite manufacturing and processing can be divided as follows: Procurement from Granite Quarries. Large granite blocks were acquired from granite quarry owners. These are generally 1 ft 3 to 2 ft 3, but can be even bigger.

This fabrication process is done by a professional stone fabricator, which is a very specialized person. In some cases the granite supplier also specializes in stone fabrication and everything can be done at their shop prior to being delivered to your home.

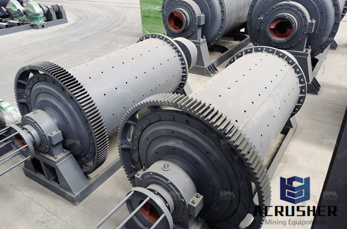

Making Granite Process. Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment. 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and service provider.

#0183;#32;First, large blocks of stone are cut from the quarry. From those blocks, thin pieces of stone are cut, called slabs. The slabs are then shaped and polished and shipped for installation. What has changed dramatically over the years is the type of machinery used in this ageold sequence.

The manufacturing process of most quartz countertops begins with inspecting the raw materials for quality and you can achieve essentially uniform color. Stones like granite and marble have natural variation along the slab that might be too unpredictable for your interior. Quartz slabs can also be mixed with dyes, and achieve basically any

Automation. Streamlining the production process is a crucial element in providing competitive pricing and consistent, high quality products. We''ve achieved through various forms of automation: saving both time and material. 24/7, our saws cut blocks, polishers finish slabs, while blowing rooms cut lettering and carve patterns. Nonstop production translates into better products at a better price.

#0183;#32;The manufacture of granite countertops begins with mining dimensional granite from quarries. Dimensional means that the rock is cut in whole pieces as opposed to quarried for crushed stone. In the United States, granite is mainly quarried in New England (New Hampshire is known as the Granite State), Texas, Indiana, Wisconsin, and Georgia, but there are granite quarries located in

The polished beautiful granite countertop that you install in your kitchen or bathroom undergoes an extensive process of stone fabrication to achieve the finished product. It is remarkable just how much occurs during this process and how important it is to getting the most from your countertop for years to

WhatsApp)

WhatsApp)