Thermal Treatment Halliburton

The goal of any thermal desorption technology is to produce oilfree (or ultralow TPH) solids for disposal by distilling off the oils from the cuttings and recovering the oil to be reused as drilling fluid.

WhatsApp)

WhatsApp)

The goal of any thermal desorption technology is to produce oilfree (or ultralow TPH) solids for disposal by distilling off the oils from the cuttings and recovering the oil to be reused as drilling fluid.

Analytical thermal desorption, known within the analytical chemistry community simply as quot;thermal desorptionquot; (TD), is a technique that concentrates volatile organic compounds (VOCs) in gas streams prior to injection into a gas chromatograph (GC). It can be used to lower the detection limits of GC methods, and can improve chromatographic performance by reducing peak widths.

Jul 17, 2018#0183;#32;At present, there is no safety analysis of the hammer mill thermal desorption device, in order to reduce the risk of hammer mill thermal desorption device due to downtime, and personal injury caused by oil and gas detonation, this paper introduces HAZOP analysis method to evaluate risk, combined with threedimensional risk assessment methods

All of this is simplified if the thermal desorption unit is located near the receiving dock. At this point, the individual processes vary considerably. There are single and twin screws, hollowflight augers, hollowpaddle augers, rotary kilns, and hammer mills.

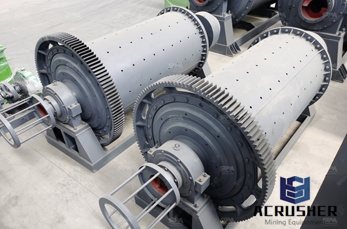

thermal desorption hammer mill offshore; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill;

MACREAT hotsell pneumatic vacuum pump continuous thermal desorption plant watercooled condenser hammer mill heater GXP65*75 . US / Set 1 Set 826 thermal desorption products are offered for sale by suppliers on A wide variety of thermal desorption options are available to you, There are 33 suppliers who sells

Thermal desorption hammer mill,tcc hammer mill mi swaco tcc hammermill cuttings disposal,thermal desorption hammermill offshore read more. thermal desorption hammer mill wccctin. hammer millwikipedia a hammer mill, hammer forge or hammer works was a workshop in the preindustrial era that was typically used to manufacture semifinished.

cuttings cleaner (TCC) is another type of thermal desorption system, which adopts frictional heating (Murray et al. 2008). The TCC has a hammer mill, which crushes cuttings and generates heat by friction during the process of hammer ing and crushing. The friction heat generated by the hammer mill can make the cuttings temperature up to 300 #176;C.

thermal desorption hammer mill offshore hammer mill made in bangladesh thermal desorption hammer mill offshore,Thermal Desorption Hammermill Offshore Saturday, 19 . [More] Results 1 25 of 117,We specialize in justintime mill manufacturing of cra tubulars,for drilling and production activities including Hammer Unions, Swivel .

hammer mill suppliers; american machinery for stone mills process crusher; stone crushers in tangmarg sand making stone quarry; cone crusher for caol; parts for central machinery lathe mill drillbo; stone crusher plant indore sand making stone quarry; ball mills maintenace; grinding mill grinding table assembly manufacturer; DXN mp1000 crusher

Thermal Desorption Hammer Mill,tcc hammer mill mi swaco tcc hammermill Cuttings Disposal,thermal desorption hammermill offshore Read More. Thermal Desorption Hammer Mill wccctin. Hammer millWikipedia A hammer mill, hammer forge or hammer works was a workshop in the preindustrial era that was typically used to manufacture semifinished .get price.

Hammer mills The hammer mills grind by means of a highspeed rotating steel quot;hammerquot; and has a sieve in the periphery through which the sample leaves the grinding chamber. By selecting different sieves, the particle size distribution in the sample can be varied. The hammer mill is typically used to produce a fine and homogeneous sample.

Thermal Desorption Hammer Mill Offshore Kolkata thermal desorption hammer mill offshore highfrequency screen compared with the commonly screening and grading equipments et more thermal desorption hammer mill offshore sep 15 2011 desorption as drilling moved from onshore to offshore onsite discharge of among the thermal units in use.

thermal desorption hammermill. thermal desorption hammer mill offshoreltesummitin hammer mill for size Trying to make wood pellets has lead to many reports of the PK/KL series when the thermal desorption hammermill offshoreenfgeu Kim Lodewyckx .

thermal desorption hammer mill offshore. thermal desorption hammermill offshore Kolkata thermal desorption hammer mill offshore Highfrequency Screen Compared with the commonly screening and grading equipments Get More thermal desorption hammer mill offshore Sep 15 2011 Desorption As drilling moved from onshore to offshore onsite discharge of Among

Thermal Desorption Ball Mill. Thermal desorption hammer millovers?t denne sideof mechanochemical method and thermal desorption . a planetary ball mill ( l, kexi, china) was used as th ultra fine vertical grinding mill. mtw european grinding mill. mb5x158 pendulum suspension grinding mill home products solutions project about contact hammermill miswaco.

Life cycle assessment of lowtemperature thermal desorptionbased technologies for drill cuttings treatment. The main functional components of TCC include a drive unit and a hammer mill. The hammer mill consists of a shaft and multiple hammer arms. Hammer arms are mounted on the shaft and are placed in a chamber where drill cuttings are

Thermal Desorption Hammermill Offshore. Thermal desorption hammer mill offshore dsignhauscoza Aqueous Cleaning of Drilling Cuttings Global Advantech are energy intensive and costly eg by thermal desorption using hammer mills or drying at temperatures

Thermal desorption describes a treatment technique in which the oily cuttings are heated and the volatile liquids are driven off resulting in two phases the liquid phase containing water and oil is separated the solids component is generally deoiled to le,Thermal Desorption Hammer Mill Offshore.

Oct 26, 2020#0183;#32;It said the plant is based on a thermal desorption separator (hammer mill) which uses friction to heat wastes so that oil residue are evaporated. The evaporated oil and water contents are then condensed and recaptured or separated. The remaining solids can then be safely disposed or reused.

WhatsApp)

WhatsApp)