Gold Refining Crucibles

The guard pot placed for safety under the white pot and afterwards used for remelting the refined gold, is a plumbago crucible 8 #188; inches high, 6 inches inside diameter, 5/8 of an inch thick at the top, and #190;

WhatsApp)

WhatsApp)

The guard pot placed for safety under the white pot and afterwards used for remelting the refined gold, is a plumbago crucible 8 #188; inches high, 6 inches inside diameter, 5/8 of an inch thick at the top, and #190;

Explains every aspects of the Gold Refining Process with its step by step methods, practices and various techniques.

In general, gravity separation is directly adopted to recycle this kind of gold. The gold ore refining equipment required is relatively simple, like chutes. However, for some gold ore with very small fineness, chemical dressing method like cyaniding and leaching is essential. And this method requires more gold ore refining

refining flow chart for gold The Real Cost of Mining Gold Kitco Commentary Feb 4 2015 Cash cost is the cost to mine goldbearing rocks process the ore and sell the gold. It factors in basic mining processing transport and refining

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process . The principle in brief is the carbon could adsorb liquid gold from cyanide solution . In 1970s, with the

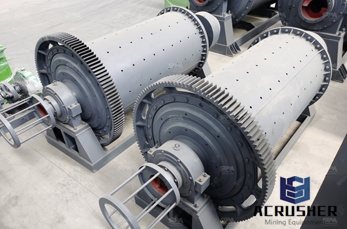

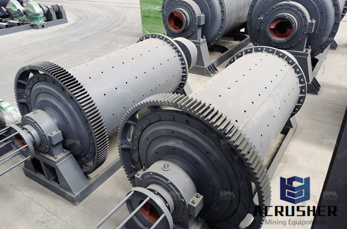

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore

Ore Dressing Refining Of Gold Process By Assayer As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we

Cyanidation carbon adsorption process is the most widely used in gold cyanide extraction process . The principle in brief is the carbon could adsorb liquid gold from cyanide solution . In 1970s, with the

Produced by ITAO Mining Reagent Co., Ltd, CNFREE ecofriendly gold leaching reagent is a hightech product for gold extraction, which can replace sodium cyanide without changing the original leaching process

Sulfide Ore Processing; Placer Gold; View Our Process Video. Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore

Ore processing consists of the following stages: crushing and grinding of the ore addition of process water (generally decanted from the tailings pond) to form a slurry addition of lime to the ore, and

Technical performance of hyperbolic wave shaker. 111220; 11 Views; icon 0; When the gold ore dressing equipment shaker runs asymmetrically in the longitudinal direction, the selected ore sand

processing plant gold flow chart Gold Ore Crusher. Gold Ore Refining Process Flow Chart, Gold Extraction Process Flow Chart. Exxon gold ore refining processing machines including

A quot;refractoryquot; gold ore is an ore that has ultra fine gold particles disseminated throughout its gold occluded minerals. These ores are naturally resistant to recovery by standard cyanidation and carbon adsorption processes. These refractory ores require pretreatment in order for cyanidation to be effective in recovery of the gold. A refractory ore generally contains sulfide minerals, organic carbon, or both.

WhatsApp)

WhatsApp)