Jurnal And Vertical And Roller And Mill Pdf

Rumus Efisiensi Alar Vertical Roller Mill Pdf Jurnal Tun 2008,Data Repository Universitas Andalas. ANALISIS KEGAGALAN VERTICAL ROLLER TYRE INDARUNG IV. Get Price. FL Energyefficient grinding mill

WhatsApp)

WhatsApp)

Rumus Efisiensi Alar Vertical Roller Mill Pdf Jurnal Tun 2008,Data Repository Universitas Andalas. ANALISIS KEGAGALAN VERTICAL ROLLER TYRE INDARUNG IV. Get Price. FL Energyefficient grinding mill

#0183;#32;re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

#0183;#32;The invention relates to a vertical roller mill system. The vertical roller mill system comprises a vertical roller mill, a distribution mechanism, a Vtype powder concentrator, a circulating fan, an efficient powder concentrator and a bag dust collector. The down stream of the distribution mechanism is communicated with a feeding inlet of the Vtype powder concentrator.

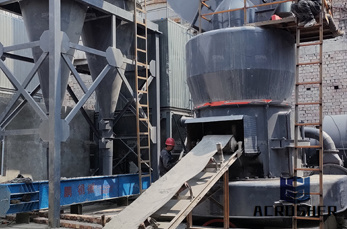

The vertical roller mill has a big feed size (can grind the material with particle size of 5% of the grinding roller diameter: the feed size is generally 40100mm, and the large vertical mill can reach 120mm), which simplifies the crushing system and saves secondary crushing.

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a

The uneven pressure distribution between the roller and material layer is caused by the drumshaped characteristics of vertical mill grinding roller. This paper studies the pressure distribution of roller in compacted zones, established mathematical models of pressure distribution analysis, and provides a theoretical basis for improving the vertical mill production process as well as yield and

#0183;#32;DOI: /S(09)600181 Corpus ID: . Grinding process within vertical roller mills: experiment and simulation article{Wang2009GrindingPW, title={Grinding process within vertical roller mills: experiment and simulation}, author={Jianhuai Wang and Q. Chen and Y. Kuang and A. J. Lynch and Jinwu Zhuo}, journal={Mining Science and Technology (china)},

Vertical roller mill,working principle of vertical roller mill. in a ball roller, grinding wheels move within a steel drum to crush rock or stone. these rollers move in a relatively random pattern, and tend to produce materials of varying sizes. they do not offer the consistency and efficient processing of a vertical roller mill.

#0183;#32;So, the control of vertical mill system is difficult by traditional theory. Consequently, this paper present an automatic control system solution for vertical roller mill, aim to achieve the goal of high quality, lowcost, safe and civilized production and increased labor. 2.

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to. maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

of the grinding material is poor; (4) The system power consumption is 80kwh/t, and the roller press system has a large circulation amount, and it has to be transported by the belt conveyor and the lifting conveyor, so the system is dusty; (5) System operation rate: 85%90% Vertical mill process features: (1) The structure is simple, the vertical mill installation is adopted, the floor space is

Vertical roller mill and ball mill both of them can be used in many different kinds of stone powder making. However, as two common use stone powder, there are many difference between these two mills, in this article, we will mainly talk about the difference between vertical roller mill and ball mill.

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process. Descriptions . Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindings.

WhatsApp)

WhatsApp)