(PDF) Determination of excavator type according to rock

mining enterprises will be able to determine the most econom ical excavator type according to both rock mass characteristics of the site and their own production capacities. Als o, knowing the

WhatsApp)

WhatsApp)

mining enterprises will be able to determine the most econom ical excavator type according to both rock mass characteristics of the site and their own production capacities. Als o, knowing the

Also called power shovels, the hydraulic shovel is the most powerful type of excavator. While it''s most commonly used for mining projects, the hydraulic shovel is suited to handle any job that requires heavy lifting and hauling of large rocks, minerals and other heavy objects or materials. 6. Dragline Excavators

#0183;#32;A dragline excavator is a piece of heavy equipment used in civil engineering and surface mining. Draglines fall into two broad categories: those that are based on standard, lifting cranes, and the heavy units which have to be built onsite.

They are typically found on stripmining sites and tarsand mining sites. Long reach excavators. A long reach excavator is a type of excavator that has an extended arm for more efficient operations in hardtoreach locations. The extended arms for long reach excavators

Each segment requires the use of specific equipment, but there are several types of mining equipment that are used throughout the industry. This equipment includes excavators, draglines, drills, roof bolters, continuous miners, longwall miners, rock dusters, shuttle cars and scoops.

#0183;#32;As the leading manufacturer of heavy equipment for construction and mining, #174; offers a wide variety of excavator sizes and types for any application. Cat mini excavators are available in several different models and are perfect for landscaping, urban and residential construction and small building projects.

Find Out More about Mining Technology. provides mining technology products for open pit and underground mine applications. Technologies that enable fleet management, drilling amp; blasting, loading, hauling, dozing, truck assignment, material tracking and operator management.

Types of Buckets for Excavators and Heavy Plant. 29 January 2018. Modern Plant Machinery and Excavator buckets are built to dig. The environments where excavators we hire are used are not always the same nor is the task they are hired to achieve.

Mining techniques can be divided into two common excavation types: surface mining and subsurface (underground) mining. Today, surface mining is much more common, and produces, for example, 85% of minerals (excluding petroleum and natural gas) in the United States, including 98% of metallic ores.

Excavator information and general content about excavators. 13 Oct 2013 They are build to release heavy work such as mining. They are This is one of the most wellknown type of excavator

The types of minerals that are mined can include coal, precious or semiprecious metals, crude oil, and natural gas. There are many types of heavy digging equipment used for mining operations, as we will focus on the top 6 heavy machines. Dragline Excavator. Dragline excavators are commonly used for strip mining operations when obtaining coal.

EXCAVATOR BUCKETS. Austin designs and manufactures mining excavator buckets to suit most OEM machines, ranging from 100 tonnes to 900 tonnes up to 50 m 3 in size.. Our designs are customised for specific applications and to meet OEM specifications, such as tip radius, pin centre, breakout force and maximum suspended load.

Mining trucks. Job reports. mining machines are working in various environmments. A job report is made about the machines performance, qualities, and abilities. Read concrete case studies. Job reports. Video. Watch an R 9800 mining excavator being delivered from the production site in Colmar, France to the Moolarben coal mine in New

#0183;#32;Well go over what each type of excavator type is and what work each one is best used for. Crawler Excavators. Unlike other large excavators that run on wheels, crawlers run on large two endless tracks, crawlers are often used in mining and heavyduty construction jobs.

This form of mining doesnt require tunnelling into the earth and is a simple method of mining that yields high production rates. The Fimiston Open Pit and the Newmont Boddington Gold Mine are two of the largest openpit mines in the world, measuring over long, wide and 570m deep.

This study presents the effect of excavator model, loading operation location, shift availability and truckshovel combination on loading cycle time and productivity of an openpit mine. The loading cycle time was used to assess the material loading system performance which is one of the key components of the total cycle time for material transportation in an openpit mine.

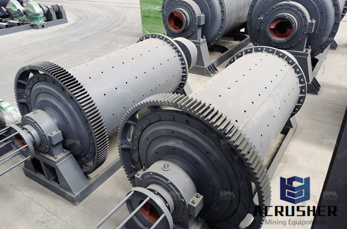

Mining excavators are called on to do a variety of tasks, from working a shot face to top loading trucks with overburden to cracking out a bank. large excavators are designed to do all those tasks fast and efficiently to maximize production. You have your choice of backhoe or shovel and diesel engines or electric motors to match the machine to your job.

Crawler Excavator The crawler excavator is certainly the main excavator type on the market. It runs on a chainwheel system and is specifically manufactured for heavy operations, such as mining operations. Most commonly, the crawler excavator is huge, incredibly stable and superior power capabilities.

WhatsApp)

WhatsApp)