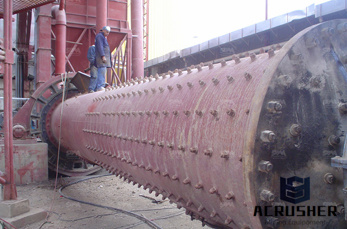

copper ore wet ball mill plant

Flotation is widely used in gold Processing. In China, 80% rock gold is Processed by flotation. Flotation Gold Flotation Production Line

WhatsApp)

WhatsApp)

Flotation is widely used in gold Processing. In China, 80% rock gold is Processed by flotation. Flotation Gold Flotation Production Line

A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium. Applications. Ball mills are found in settings as diverse as laboratories and mines, among others. Technologies. Ball mills can grind in either a wet or a dry environment.

pendulum getz wet ball mill. pendulum getz wet ball mill As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide

Jul 14, 2020#0183;#32;Grinding Mill, Raymond Mill, Ball Mill, Superfine Grinding Machine, Rotary Kiln, Vertical Rolling Mill Company Introduction Since founded in 1973, GUIKUANG has witnessed the development of three generations of China Pendulum Mill, along with the growing steps of customers.

pendulum wet ball mill pictograms. Pendulum Grinding Mill Environmental XPRT. Pendulum mill is also called as suspension roller or Raymond mill is a ring and roller powdermaking mill equipment which is combined with air flow screening and pneumatic conveying.

DOTSOG Newton''s Cradle, Desk Table Decor Metal Pendulum Ball Newton Ball Physics Science Pendulum Steel Balance Ball for Office Physics Teacher Toys. out of 5 stars 277. 18. 98. FREE Shipping on orders over 25 shipped by Amazon. In stock on December 27, 2020. Ages: 12 months 12 years.

Main specifications of Steel Ball Mill type TNM Series for wet process. The SKTM can also be delivered in a version for wet proces. The TNM Series of ball mills are available from 20 100 litres. These mills are including a Al2O3 lining with thickness of 38,1 mm and further design is

The final products sizes can be adjusted between to by changing the diameter of the balls in the ball mill. According to the grinding method, ball mill can be divided into wet and dry ball mill. According to the different ways of discharging the processed materials, ball mill can be divided into overflow ball mill and grate ball mill.

Happybuy Electric Grain Grinder 300g Pulverizer Grinding Machine 1680W Mill Grinder Powder Machine 50300 Mesh Stainless Steel Swing Type Grain Grinder Mill for Kitchen Herb Spice Pepper Coffee out of 5 stars 10. Chat Now; Grinding MachinesStarSU. Generating Grinding machines feature simple design concepts and user friendly operation.

The highspeed vibrating ball mill can use dry and wet methods to ball mill or mix various solids, suspensions and pastes with different particle sizes and materials. Feature: 1. Small size, light weight, high efficiency and low price. 2. A highefficiency small instrument used for the preparation of laboratory samples (small and small amounts). 3.

NETZSCH ECUTEC''s Altai Pendular Roller Mills combine high classifying efficiency with the advantages of a multipurpose mill. Drying, grinding and classifying can be done in open or closed systems. Finenesses down to 45 #181;m can be achieved in just one step.

5X Pendulum Roller Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Read More. stone crusher, LM mill, impact crusher, hammer crusher, grinding.

GUIKUANG GKW1270 Micro Powder Mill is a new environmental superfine powder mill for grinding mesh powder. It''s very popular because of its high value. Ball Mill Raymond Mill Vertical Grinding Mills GK2500 Pendulum Grinding Mill

Pendulum Feeder. Efficient Thickener. Disc Feeder. Wear Resistant Rubber Products. Magnetic Separator. Cylinder Energy Saving Overflow Ball Mill. Press Filter. Jaw Crusher. High Spiral Classifier. Kyf Air Inflation Flotation Cell. wet ball mill minerals mineral

gold ball mill owners in ernakulam district. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent.

pendulum wet ball mill machine usa Pendulum Mills for fine mineral grinding Verdes. The efficiency of the fine grinding combined with the fact of being able to grind, classify and if necessary dry in one single machine undoubtedly gives Pendulum Mills a clear advantage over other systems. They admit a supply with grain sizes of up to 50 mm

Wet Ball Mill 100 20000 litres Ball mills ( wet or dry processes) for intermittent grinding of hard materials and batches in different branches of the ceramic and chemical industry. To ensure ironfree grinding these mills are lined with steatite, Al2O3 or Polyurethane.

roller mill(HCH): It can produce ultrafine powder, low energy consumption low investment cost, large scale ring roller mill has good market prospect. Disadvantage: low output. mill +classifying: High energy consumption, it is almost obsolete in nonmetallic mineral industry.

The Pendulum Ball Exercise. This is an excellent exercise for visual tracking and convergence work. A pendulum ball is simply a ball tied on a string and hanging down from the ceiling or light fixture. The ball can travel side to side like a pendulum does, it can travel in a circle (clockwise or counter clockwise) and it can move in and out

Brief Introduction of Ball Mill. Ball mill is the key equipment for regrinding the materials after they are coarsely crushed. It is widely used for the dry or wet grinding of all kinds of ores and other grindable materials in the production industries of cement, silicate product, new building material, refractory, fertilizer, ferrous and nonferrous metal dressing and glass ceramics.

Newtons Cradle Pendulum Balls Balance Ball Swinging Balls Physics Science Desk Gadgets Office Desk Decorations Toys, TShape. out of 5 stars 103. 10. 99. Get it as soon as Mon, Dec 28. FREE Shipping on orders over 25 shipped by Amazon. Only 8 left in stock order soon.

Nov 01, 2002#0183;#32;Schellinger''s calculated ball mill efficiency, in dry or wet ball mill grinding, ranges between 10% and 19%, with the higher figure occurring at the optimal mill loading. In terms of the Brace and Walsh surface free energy of quartz, his results give a ball mill efficiency that is less than %.

WhatsApp)

WhatsApp)