(PDF) Overview of Mineral Processing Methods

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing

WhatsApp)

WhatsApp)

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing

Gold is a very soft element and because of the gold alloys, gold may vary in cleavage. Pure cold has no cleavage, it has a fracture. It fractures in hackles with torn surfaces.

The gold prices used in this table and chart are supplied by FastMarkets. Where the gold price is presented in currencies other than the US dollar, it is converted into the local currency unit using the foreign exchange rate at the time Processing, smelting and refining gold.

The most common and notable example of this are precious metal values (gold, silver etc.) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit. Processing Approach and Method

Native gold is an element and a mineral. It is highly prized by people because of its attractive color, its rarity, resistance to tarnish, and its many special properties some of which are unique to gold. No other element has more uses than gold. All of these factors help support a price of gold that is higher than all but a few other metals.

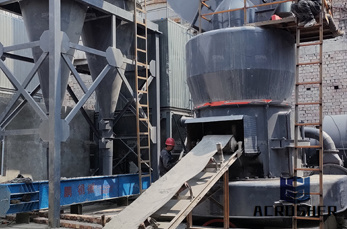

Ball Mill Gold Mineral Processing Low Consumption. energy saving grinding ball mill ball mill application the ball mill is widely applied in mineral classification, cement, fireproof materials, glass, pottery, chemical henan yuhui mining machinery coltdineral processing mining stone grinding ball mill working principle the transmission.

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position. These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methods.

#0183;#32;Gold bulls were disappointed that the price did not break through the 2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a strong interest in gold projects. Gold processing has a couple of unique features.

Minerals and Metals Fact Book 2016. Minerals and Metals Fact Book 2016. 1. Introduction. Canadas minerals sector, which comprises mining, miningrelated support activities, and mineral processing, is a mainstay of the national economy that supports stone and economic activity in every region.

Gold processing Britannica. Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earths crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions. Contact Supplier

2 #0183;#32;Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

cleavage of gold mineral processing,Gold extraction refers to the processes required to extract gold from its may require a combination of comminution mineral processing hydrometallurgical and pyrometallurgical processes to be performed on the ore.. hard rock gold mineral processing map,hard rock gold mineral processing map Geology Of

Gold does not have a cleavage it has a fracture: The type of fracture is hackly or jagged. Cleavage usually relates to crystals (although cleaving crystals can also be made to fracture too).

The Basic Technology Mineral Processing Ores Gold, Silver, Copper And Basic Techniques The Mining And Mineral Science Technology. Chemical Reaction Aqua Regia for Gold Cleavage: imperfect cleavage and its fracture conchoidal. This mineral fragile. Crystallography: Isometric: Cubic .

WhatsApp)

WhatsApp)