coal mill in cement process stone crusher machine

Cement Crusher Crusher In Cement Plant AGICO CementRaw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reac

WhatsApp)

WhatsApp)

Cement Crusher Crusher In Cement Plant AGICO CementRaw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reac

We have ppt for cement manufacturing process,Jun 10, 2014#183; Types ofCement Processes WetProcess. DryProcess 74% ofcement produced. Preheater/PrecalcinerProcess. 16. Evolution of thecement Process Wetprocesseasiest to control chemistry amp; better for moist raw materials. Wetprocesshigh fuel requirements fuel needed to evaporate 30+% slurry water.

The Indian cement industry has made rapid strides in the recent years. With a rise in infrastructure and housing projects in the coming years, demand for cement will increase tremendously. This is where modern machines and latest technological developments will help cement manufacturers keep pace with the increased demand.

Cement making process Cement Mining Equipment Supplier. Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, it is quite important to choose appropriate grinding equipment and technological process so that highquality products can be obtained. (3). Raw Meal Homogenizing.

We have cement manufacturing process cement machinery manufacturers,China Sunrise Machinery (CSM) is a professional cement equipment manufacturing enterprise, the main products are cement production line including: tube mill, rotary kiln, roller press, vertical mill,rotary dryer, suspension preheater. The rotary kiln can also be combined with a variety of other devices such as cooler, exhaust

#0183;#32;Dry cement powder. Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products. Drilling, blasting, and crushing machinery convert mined limestone to fragments about inches (about 1 cm) in diameter, after which it is stored until needed.

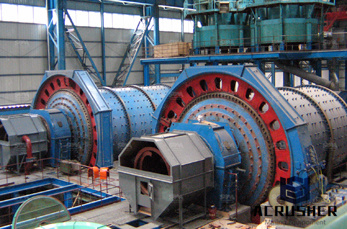

Dec 18, 2017#0183;#32;Cement Manufacturing. A raw mill is an equipment used to grind raw materials into Raw Mix during the manufacture of cement. Dry raw mills technology allows minimization of energy

Cement Equipment Cement Machinery Manufacturer amp. China Sunrise Machinery CSMcement production line is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns

The new dry process of cement manufacturing is the latest and most efficient modern cement production technology. It takes suspension preheating and pre decomposition outside the kiln as the core technology, widely applies the latest achievements of modern science and industrial production to the whole process of cement

China Sunrise Machinery (CSM) is a professional cement equipment manufacturing enterprise, the main products are cement production line including: tube mill, rotary kiln, roller press, vertical mill,

Manufacturer of Roller for Machines Roller for Cement Process Plant, Roller for Pharma Machine, Screw for Tube Mill Machinery and Roller For Packaging Machine offered by Saraswati Manufacturing Works, medabad, Gujarat.

Specialized Cement Mill. In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of cement grinding machine, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder that is cement..

Cement kiln is used for making of cement clinker and there are dry and wet methods to make cement. In the process of using, the cement has the advantage of quick hydration reaction and fast strength

The Cement Manufacturing Process Advancing Mining. Aug 20, 2015#183;Cement manufacturingis a complexprocessthat begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated

WhatsApp)

WhatsApp)