6JTV01 Ball Mill Lubrication Systems YouTube

#0183;#32;6JTV01 Ball Mill Lubrication Systems King Industries, Inc. Loading Maintenance cement grinding roller press Duration: Alemite Hydraulic Lubrication System What you

WhatsApp)

WhatsApp)

#0183;#32;6JTV01 Ball Mill Lubrication Systems King Industries, Inc. Loading Maintenance cement grinding roller press Duration: Alemite Hydraulic Lubrication System What you

Mill Lubrication System 1. OBJECTIVES: To identify the definition and importance of a hydraulic lubrication system. To be familiarized with the lubricant and equipment used in the system. To understand the process and various design of Mill lubrication system. To identify some problems encountered by the system, and formulate some recommendation to help fix the problems.

Website translations are provided by Google Translate, a thirdparty service provided by Google. The automated translations should not be considered exact and used only as an approximation of the original English language content.

Abstract: This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives. Provided within this paper are hydraulic schematics, functional description and a general overview of system layout as well as some of the important features and factors relevant to improving the reliability of this very critical part of the grinding mill drive system.

#0183;#32;Intermittent spray system maintenance may be reduced and system reliability increased with the use of these open gear lubricants. Due to their goodtoexcellent pumpability characteristics, the spray systems pumps, metering devices and conduits are subjected to less stress.

AUTOMATED CONVEYOR SYSTEMS, INC 3850 Southland Drive West Memphis, AR 72301 This check list gives the user a comprehensive guide of periodic maintenance. This check list is to be used as an additional reference of lubrication and maintenance to supplement preventive maintenance instructions noted in the manual. SCHEDULED MAINTENANCE

Installation, Maintenance, Lubrication, and Repair. Thomson has decades of experience in designing, manufacturing, and maintaining high quality ball screws. We can help guide you through the installation process,develop good lubrication and maintenance practices all assure long life and a smooth running ball screw assembly system.

#0183;#32;The training should include operations, adjustments and maintenance of the system. The following are the 10 most common ways a centralized lubrication system can fail to deliver the lubricant at the proper time, in the proper place, and in the proper quantity. 1. Plugged or collapsed lines. 2. Broken lines. 3. Empty lubricant reservoirs. 4

Cement Ball Mills. A cement ball mill is designed to grind clinker, Maintenance Tips. The d thing was that this only happened at one of the lubrication systems. Each bearing had it''s own system. We drained the oil and we saw the cause immediately.

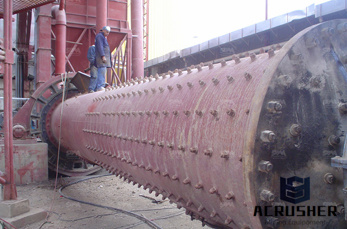

On a 116 x 220 Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor

Ball mill is the largest consumption equipment of mining plant. The ball mills operating state directly influences the whole mill plant productivity. Its also the biggest investment equipment of mill plant, and the wastage of the ball mill has a...

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

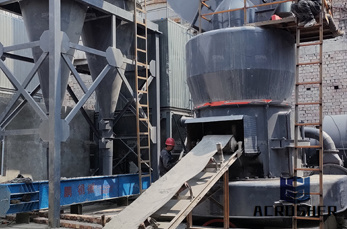

Ball Mill Gear Lubrication System . ensure the equipment performance in good condition and reduce the maintenance cost is of great significance. On the market at present, the ball mill drive gear pair lubrication method for small tank of oil lubrication,

Spray systems require users to provide instrument compressed air spray system, equipped with oil pressure detection switch, a nozzle detection switch and other instruments to ensure the stable operation of the lubrication system of a ball mill. Ball Mill Gear Lubricating Oil Using Method. 1.

WhatsApp)

WhatsApp)