Reducing Grinding Energy and Cost Magnetite Iron Ore

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study produce a magnetite product suitable for sale as undersize bypass returning to the mill. Using a magnetic separator

WhatsApp)

WhatsApp)

Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study produce a magnetite product suitable for sale as undersize bypass returning to the mill. Using a magnetic separator

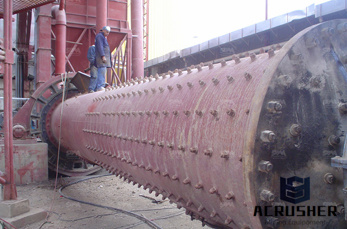

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous is a high technological enterprise that integrated research

Magnetite Ore Crushing Grinding Equipment Used For Portugal. Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

Ball mill. The ball mill is the fine grinding machine connect the SAG or AG mill and flotation machine. Ball mills produce fine particles with a uniform size for flotation, its grinding medias commonly are steel ball. The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but

Grinding Magnetite In Ball Mill Magnetite Grinding In Laboratory Ball Mill r. Mills total media wear in a given ball mill grinding process is a product of three recognised wear mecha alball arball surface area of balls in lab mill and in real mill m2 studies on ball wear in the grinding of a hematitimagnetite ore read more.

Copper Copper ore a valuable mineral source for all countries. Copper ore is an ore which can produce copper metal by crushing in ore crushing plant, grinding in Ball mill and smelting in a furnace along with a piece of tin ore. SBM is a proessional manufacturer of copper ore crushing equipment and grinding

ensp0183enspMagnetite, iron oxide, iron ore similarities and differences Iron Oxide, MagnaChem, MagnaDense, Magnetite, MagniF, News 5 November, 2019 From the natural magnetite products mined in Sweden, LKAB Minerals produce several products.

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Magnetite Ore Crushing Grinding Equipment Used For . crushed iron ore beneficiation process linde. Iron ore beneficiation equipment is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are.

mill in the world which has a diameter of m, length of 11 m, and equipped with a 28 MW gearless motor [4]. The LKAB iron ore operations in Sweden process highgrade magnetite ore through an AG milling circuit with a throughput of 500 to 582 t/h to achieve product P80 of 45 m [5].

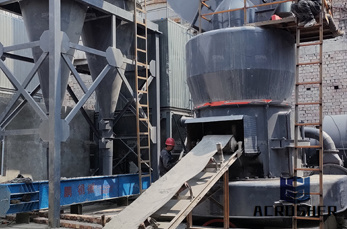

Powder grinding mill can be used for the highfine power processing. Ore processing machine. Mineral processing equipment is polishing and sorting equipment. Building Materials Equipment. The series includes rotary kiln, cement kiln, rotary dryer, etc.

Magnetic Separation: Separates magnetic ore (pyrrhotite) from nonmagnetic ore (copper and nickel concentrates). Froth Flotation: Nonmagnetic ore is sent to a series of rougher and cleaner flotation cells to produce nickel concentrate. Drying: Thermal removal of liquid moisture . Calcining: Thermal decomposition of a material.

WhatsApp)

WhatsApp)